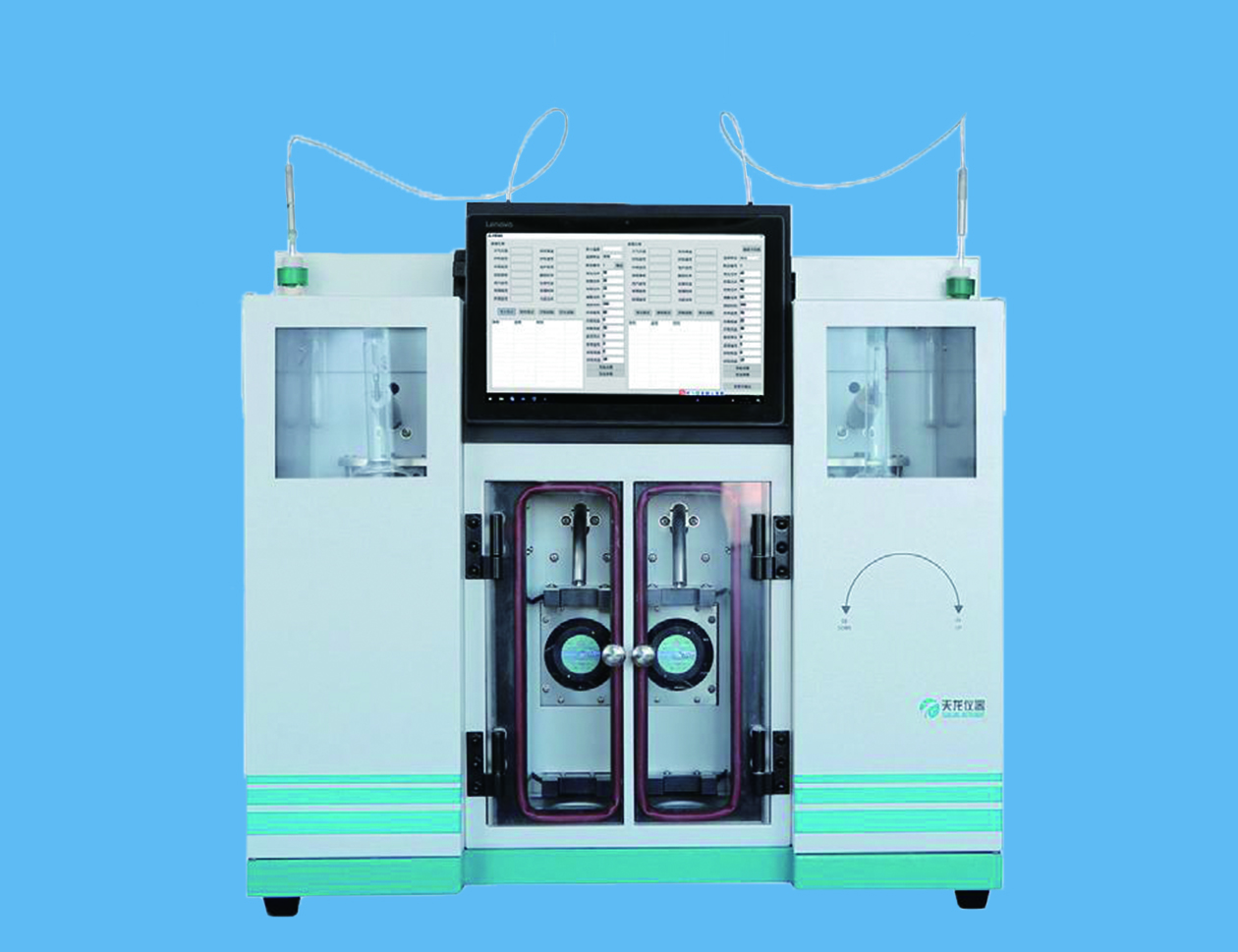

TLLC-30D Double Tube Fully Automatic Distillation Range (Boiling Range) Tester

| Manager Liu: | 13351885528 |

|---|---|

| Manager Liu: | 13945136889 |

| Online More Information | |

| Share: |

|

Product Introduction

Introduction to Main Technical Parameters and Performance:

Applicable standards: GB/T 7534, GB/T 2282, GB/T 6536, ASTM D86, ASTM D850, ASTM D1078, etc

This instrument utilizes technology and an intelligent heater adjustment model, which can automatically apply heater settings to ensure that atmospheric distillation meets specified standards, even for complex samples such as mixtures.

Main technical indicators:

The heating device is a high-power PID current source, with an adjustable supply voltage of 32V and current of 0-60A for the electric furnace wire. It is PWM adjustable, and the heating device can be manually or automatically lifted, with a power of 0-1800W.

Automatic control of distillation rate, zero point self calibration, automatic detection of recovery volume, automatic adjustment of power, ensuring recovery volume of 4-5ml/min (adjustable), using microporous insulation board to completely prevent overheating and ensure the true boiling range measurement of methanol.

The temperature control range around the recycling cylinder: 0 ℃~60 ℃ (the temperature of the left and right cold baths can be controlled separately) ± 0.1 ℃.

Blind sample learning function, establishing curves after several analyses of blind samples, and achieving standard distillation experiments of blind samples.

Cold bath temperature: Imported compressor refrigeration, using alloy casting technology, the metal bath has a fast heating and cooling speed. It only takes 2-5 minutes to drop from 40 ℃ to 0 ℃, with a temperature range of 0-90 ℃. The temperature control accuracy of the cold bath is ± 0.1 ℃.

Steam temperature measurement range: 0-500 ℃, accuracy: 0.01 ℃.

The distillation flask is equipped with a steam temperature sensor and a high-precision dry point detection sensor on the PTFE bottle stopper

The distillation bottle adopts a standard frosted mouth according to the standard, and the thickened quartz bottle

Volume detection range: 0-100ml Resolution: 0.1ml (liquid level tracking does not use infrared emission and reception tubes, but uses laser targeting technology, unaffected by environmental light)

Temperature measuring element: PT100 (German original temperature sensor)

Distillation rate 2-10mL/min (adjustable)

Correction function: can correct atmospheric pressure, steam temperature, sensors, and measuring cylinders;

Double tubes can automatically conduct two different sample experiments simultaneously (methanol experiment on one side and butanol experiment on the other side), as well as parallel samples of the same sample.

The instrument is embedded with an industrial grade tablet computer and Windows operating system. It can automatically complete distillation experiments with one click, and the experimental data can be stored infinitely. It can be converted into Word, Excel, PDF, and XML formats for analysis and statistics.

You can view the instrument's historical data through wireless network.

USB2.0 interface, network interface, lims interface, touch screen operation, external Bluetooth mouse keyboard A4 paper printer, real-time display of two distillation device distillation configuration diagrams on one screen, without the need for manual switching. The entire process instantly displays the temperature of two steam tubes, heater temperature, condensation temperature, receiving chamber temperature, distillation rate curve, recovery volume, etc. It can conveniently and intuitively read and judge whether all indicators meet the standard requirements.

The mouth of the distillation flask is equipped with an explosion-proof boiling device (which can replace the explosion-proof boiling device of imported instruments).

Dry point detection: equipped with standard internal dry point detection sensors in flasks (can replace imported instrument dry point detection sensors)

Refrigeration method: Two compressors for refrigeration (DANFOS, Denmark)

Operation method: Program startup, simple operation

Protection methods: overheat protection and overflow protection, which can be automatically turned off

Distillation method: Applicable standards and distillation procedures can be added according to user needs.

The results showed that after the experiment, the evaporation temperature was automatically calculated by inputting the residual amount.

Self check and calibrate the system after startup to make operation more reliable

Correction function: can correct atmospheric pressure, vapor temperature, sensors, and measuring cylinders

Data recording methods: temperature volume, volumetric temperature, temperature mass, volumetric mass

Main features:

◇ Intelligent heating management system to ensure that the distillation rate meets the requirements of the experimental method.

◇ User defined recording points:

① Users can set the recovery volume to record the corresponding temperature

② Users can set the temperature to record the corresponding recycling volume

③ Automatically record the recording points specified in the national standard

◇ Five ways to end experiments:

1. End of endpoint: End the experiment when the final distillation point is detected and print out lims

End of 2 dry points: End the experiment when a dry point is detected and print out lims

3. Temperature End: End the experiment based on the temperature value set by the user and print out lims

4. Volume End: End the experiment based on the user's set volume value and print out lims

5. End of initial boiling point: End the experiment when the initial boiling point is detected and print out lims

The liquid level tracking system adopts laser targeting technology to directly track the downward tangent of the curved liquid surface, meeting the visual habits of the human eye, unaffected by external light, and consistent with the manual reading mode.

Equipped with a flame detector, it has automatic nitrogen fire extinguishing function and fault diagnosis reminder function.

◇ Automatic detection of atmospheric pressure and automatic calculation of temperature under standard atmospheric pressure based on measured pressure.

Product

- Fully automatic distillation range (boiling range) tester

- Harbin New Area Joins Hands with Harbin Engineering to Build Bihai Industrial Park

- The instrument and meter industry is showing a mainstream trend of high-tech development

- What opportunities does China's entry into the WTO bring to the instrument industry? Tianlong Instrument is here to analyze!

- How to bridge the development gap in the instrumentation industry?